Cavity Barrier Regulations in the UK: What You Need to Know

Cavity barriers are a crucial yet often unseen element of fire safety in buildings across the United Kingdom. Installed within the cavity walls and sometimes floor voids of a structure, these seemingly simple components play a vital role in preventing the rapid spread of fire and smoke. Understanding the specific regulations surrounding their use is paramount for architects, builders, contractors, and even homeowners undertaking significant renovations. This comprehensive guide delves into the intricacies of cavity barrier regulations in the UK, outlining what you need to know to ensure compliance and, most importantly, to safeguard lives and property.

What Exactly are Cavity Barriers?

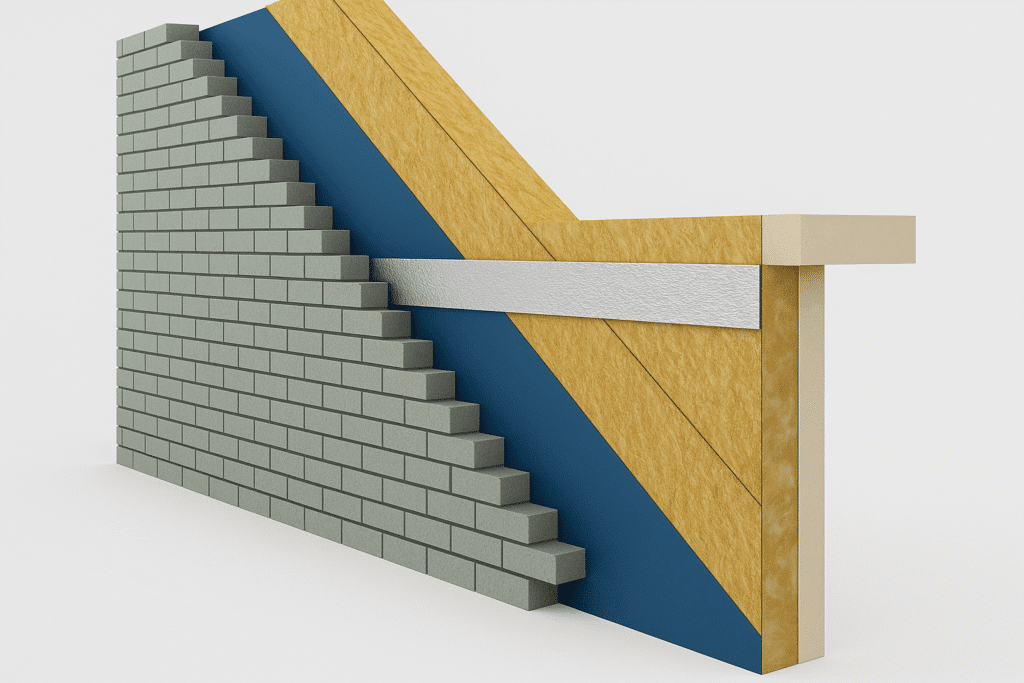

To fully grasp the importance of the regulations, it’s essential to first understand what cavity barriers are. In essence, they are fire-stopping materials installed within the concealed spaces (cavities) of building elements. These cavities, found in walls, floors, and sometimes roof spaces, can act as hidden pathways for fire and smoke to spread rapidly throughout a building if not properly compartmentalised.

Cavity barriers are designed to seal off these voids, effectively dividing them into smaller compartments. In the event of a fire, they prevent flames and hot gases from travelling unchecked through the cavity, limiting the fire’s growth and providing crucial time for occupants to escape and for fire services to respond.

Why are Cavity Barriers So Important for Fire Safety?

The seemingly simple act of sealing a cavity has profound implications for fire safety:

- Preventing Vertical and Horizontal Fire Spread: Cavities can allow fire to bypass fire-resistant layers of walls and floors, spreading quickly both upwards and sideways to other parts of the building. Cavity barriers interrupt this concealed fire travel.

- Maintaining Compartmentation: Building regulations in the UK heavily rely on the principle of fire compartmentation, where a building is divided into fire-resistant compartments to contain a fire within its area of origin. Cavity barriers are vital in maintaining the integrity of these compartments at junctions and around openings.

- Reducing Smoke and Toxic Gas Spread: Smoke and toxic gases are often more dangerous than flames themselves, impairing visibility and causing asphyxiation. Cavity barriers help to restrict the movement of these deadly byproducts of fire through concealed spaces.

- Providing Time for Evacuation: By slowing down the spread of fire and smoke, cavity barriers provide crucial extra time for building occupants to safely evacuate the premises.

- Protecting Escape Routes: Ensuring that escape routes, such as corridors and stairwells, remain free from fire and smoke is paramount. Cavity barriers contribute significantly to this by preventing fire from flanking these protected areas.

The UK Building Regulations

The primary legal framework governing the use of cavity barriers in the UK is the Building Regulations, specifically Approved Document B: Fire Safety. This document provides detailed guidance on the requirements for fire safety in buildings, including the installation and specification of cavity barriers.

Key aspects of Approved Document B regarding cavity barriers include:

- Requirement B3: Internal Fire Spread (Structure): This section deals with the fire resistance of the building structure. Cavity barriers contribute to meeting this requirement by maintaining the fire resistance of walls and floors where they intersect or are penetrated by cavities.

- Requirement B4: External Fire Spread: This section addresses the risk of fire spreading over the external walls of a building. Cavity barriers play a crucial role in limiting the spread of flame within external wall cavities, particularly in high-rise buildings or those close to boundaries.

- Specific Guidance on Location: Approved Document B provides clear guidance on where cavity barriers must be installed. This includes:

- At the edges of cavities around windows and doors.

- At junctions between cavity walls and floors or roofs.

- At intervals within cavities, both horizontally and vertically, to limit the size of any potential fire spread. The maximum spacing depends on the building type, height, and the fire risk.

- Around service penetrations that create a void within a building element.

- At changes in direction or construction within a cavity.

- Specification of Materials: The regulations specify the minimum fire resistance performance that cavity barrier materials must achieve. This is typically expressed in terms of fire resistance duration (e.g., 30 minutes, 60 minutes) when tested to relevant British Standards (BS EN). The required fire resistance depends on the building type and height.

- Installation Requirements: Proper installation is just as crucial as the specification of the materials. Approved Document B emphasises the need for cavity barriers to be tightly fitted to the surrounding construction to prevent the passage of fire and smoke. Gaps and voids around cavity barriers can compromise their effectiveness.

Types of Cavity Barriers Available

A variety of products are available to serve as cavity barriers, each suited to different locations and construction types:

- Intumescent Materials: These materials expand significantly when exposed to heat, sealing off the cavity. They are often used around service penetrations and in tight spaces.

- Mineral Wool: Fire-resistant mineral wool batts or rolls are a common choice for filling cavity spaces and creating barriers. They can be compressed to fit tightly within the void.

- Fire-Rated Timber: Specially treated timber that offers a defined level of fire resistance can be used as cavity barriers in certain constructions.

- Proprietary Cavity Barrier Systems: Many manufacturers offer pre-formed cavity barrier systems made from various fire-resistant materials, often designed for specific applications like cladding systems.

Installation Best Practices

Effective installation is paramount to ensure that cavity barriers perform as intended in the event of a fire:

- Tight Fit: Cavity barriers must be installed with a tight fit against the surrounding construction, leaving no gaps or voids that could allow fire or smoke to pass.

- Correct Location: Adhere strictly to the locations specified in Approved Document B and the project fire strategy.

- Appropriate Fixings: Use fixings that are suitable for the cavity barrier material and the substrate to ensure the barrier remains in place during a fire.

- Continuity: Ensure continuity of the cavity barrier across junctions and around penetrations. Any breaks in the barrier can compromise its effectiveness.

- Compression: When using compressible materials like mineral wool, ensure they are adequately compressed to achieve the required density and fire resistance.

- Inspection: Thorough inspection of the installed cavity barriers should be carried out to verify their correct location, fit, and integrity.

Consequences of Non-Compliance

Failure to install or correctly specify cavity barriers can have severe consequences:

- Increased Risk of Fire Spread: The primary risk is the rapid and uncontrolled spread of fire and smoke throughout the building, endangering occupants and potentially leading to structural collapse.

- Legal Penalties: Non-compliance with Building Regulations can result in enforcement notices, fines, and even legal action.

- Invalidated Insurance: In the event of a fire, insurance claims may be invalidated if the building does not comply with fire safety regulations.

- Reputational Damage: For developers and contractors, non-compliance can lead to significant reputational damage and loss of future business.

Conclusion

Cavity barriers are a fundamental component of fire safety in UK buildings, playing a critical role in preventing the hidden spread of fire and smoke. Understanding and adhering to the regulations outlined in Approved Document B is not merely a matter of legal compliance; it is a responsibility to protect lives and property. By specifying the correct cavity barrier materials, ensuring their proper installation, and maintaining their integrity, we can create safer buildings for everyone. Always consult the latest version of Approved Document B and seek expert advice to ensure your project meets the required standards for cavity barrier installation.